Import management can be the most important part of running your business. If you do not have enough products, it could cause sales loss; if you have too many, it could reflect poorly on retailers.

How do you find the sweet spot? Success depends on many factors, but a great place to start is with a thorough understanding of production and transit time.

Production Time

The first thing to be familiar with is your client’s production time, or the number of goods that they can produce in a given time period. Do they have the capacity to hold some finished production goods? How fast can they react if the demand changes? If you don’t have the answers to these questions, it’s time to reach out and ask some more questions.

Transit Time

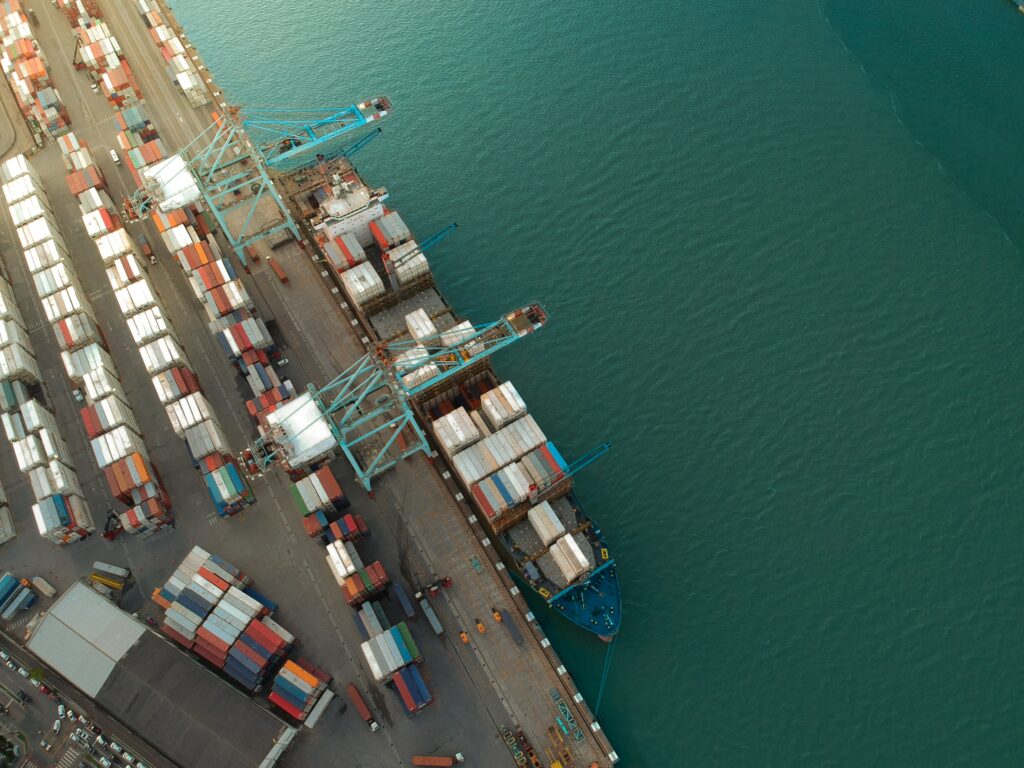

Secondly, you need to know the ins and outs of everything related to transit time. You need to know where your shipping is coming from, which port you are sending it to, and everything in between. Details are key when it comes to transit, and you must stay updated on sea transit, dredge, and the time from port to warehouse.

For example, here are the average shipping times from China to the United States. These could affect which port you are shipping to.

- Regular Shipping: 30 – 60 days

- Average Air Freight: 7 – 12 days

- Average Sea Freight: 25 – 35 days

Here are the shipping times from India to the United States:

- Regular Shipping: 28 – 67 days

- Average Air Freight: 3 – 5 days

Partnering Up

Third, you must have an understanding of what your retail partner(s) will do with the items in question. Is your product an everyday item or a promotional item? Is the retailer running any specific promotions on the item? How many weeks of supply can be stored in the retailer’s warehouse? Once you have that information, you can start pulling the retailer’s forecast, total available supply, current POs, future purchase orders, and other vital details.

Next, you should take your analysis and work with your clients to make educated decisions about adjusting your production schedule. Communicating with your retail partner is also tantamount to issuing more purchase orders or moving existing purchase orders forward.

If your product is overloaded at the retailer, then you’ll need to work on a strategy to exit the product to minimize the impact on both parties.

Final Considerations

Here are a few things that you should know about importing goods:

- Your orders will be sporadic. Your factories could have downtime where production isn’t needed.

- You usually only receive orders on a quarterly basis.

- Your retail partner could hit you with chargebacks where you write checks to them for returned goods.

To wrap things up, we recommend that if you want to be successful, make sure to stay on top of inventory and prioritize communicating with clients and retail partners. Call out changes early, whether they are good or bad. This will ensure a true partnership and proper management of imported goods.

Contact the Legacy Retail team for professional assistance in managing your business, including optimizing your import operations.